Product Features

Unique sealing design, piston / cylinder can be offset compensation;

Plunger working stroke is 10 mm;

Built in stroke limit valve to prevent over stroke use;

Working pressure of ultra high pressure hydraulic bolt tensioner is 150/200 MPa.

Field Applications

Bolt synchronous pre-tightening of pipe flange bolt;

Bolt synchronous tensioning and pre-tightening in series;

Vertical mill foundation bolt pre-tightening in cement plant;

Pressure vessel bolt synchronous pre-tightening in refinery;

Pressure vessel bolt synchronous pre-tightening in chemical plant;

Bolt pre-tightening of large electric motor in thermal power plant;

Bolt synchronous pre-tightening of pipe flange bolt;

Pressure vessel bolt synchronous pre-tightening in steel mill.

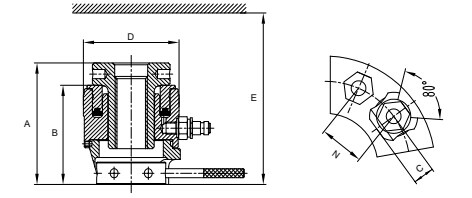

Datesheet:

| Model | Thread Specification (mm) | Bolt Distance | Min Height N (mm) | Stroke (mm) | Strench Head Weight(mm) | Min Height (mm²) | Max. Load@1500Bar(kN) | Dimensions (mm) | Weight (kg) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | |||||||||||

| SENT-UHBT-01 | M16-M30 | M16 x 2 | 55 | 169 | 10 | 1.58 | 1495.4 | 224.3 | 135 | 113 | 27 | 86 | 3 | |

| M18 x 2.5 | 56 | 165 | 1.51 | |||||||||||

| M20 x 2.5 | 57 | 165 | 1.43 | |||||||||||

| M24 x 3 | 59 | 165 | 1.31 | |||||||||||

| M27 x 3 | 62 | 167 | 1.16 | |||||||||||

| M30 x3.5 | 65 | 170 | 1.01 | |||||||||||

| SENT-UHBT-02 | M30-M39 | M30x 3.5 | 71 | 173 | 10 | 2.58 | 2677.2 | 401.5 | 136 | 111 | 35 | 107 | 4.1 | |

| M33 x 2.5 | 74 | 174 | 2.37 | |||||||||||

| M36 x 4 | 77 | 177 | 2.17 | |||||||||||

| M39 x 4 | 80 | 180 | 1.93 | |||||||||||

| SENT-UHBT-03 | M39-M52 | M39 x 4 | 92 | 212 | 10 | 5.68 | 5127.1 | 768.9 | 160 | 126 | 46 | 138 | 7 | |

| M42 x 4.5 | 96 | 215 | 5.35 | |||||||||||

| M45 x 4.5 | 99 | 218 | 4.98 | |||||||||||

| M48 x 5 | 105 | 216 | 4.66 | |||||||||||

| M52 x 5 | 108 | 220 | 4.18 | |||||||||||

| SENT-UHBT-04 | M52-M68 | M52 x 5 | 118 | 240 | 10 | 10.74 | 9782.1 | 1466.9 | 180 | 141 | 62 | 174 | 12.2 | |

| M56 x 5.5 | 121 | 244 | 10.1 | |||||||||||

| M60 x 5.5 | 124 | 248 | 9.44 | |||||||||||

| M64 x 6 | 127 | 252 | 8.78 | |||||||||||

| M68 x 6 | 130 | 256 | 8.09 | |||||||||||

| SENT-UHBT-05 | M68-M80 | M68 x 6 | 145 | 278 | 10 | 17.28 | 15079.7 | 2261.4 | 202 | 157 | 78 | 210 | 18.7 | |

| M72 x 6 | 149 | 282 | 16.39 | |||||||||||

| M76 x 6 | 152 | 286 | 15.47 | |||||||||||

| M80 x 6 | 162 | 293 | 14.55 | |||||||||||

| SENT-UHBT-06 | M80-M95 | M80 x 6 | 169 | 312 | 10 | 22.28 | 18972.1 | 2845.1 | 219 | 173 | 82 | 240 | 2708 | |

| M85 x 6 | 169 | 312 | 21 | |||||||||||

| M90 x 6 | 178 | 317 | 19.35 | |||||||||||

| M95 x 6 | 181 | 322 | 18.04 |

Application